Electrical inspections and safety

10 April 2024

Fires of electrical origin are responsible for substantial numbers of claims every year. It is therefore vital that electrical systems are well maintained and inspected regularly to reduce the risks.

What are my responsibilities?

Where employees may be present the law requires a system of inspection, testing and maintenance of electrical systems, including wiring, switchgear, any fixed machinery and portable electrical appliances to be in place to prevent danger.

- Commercial property owners are duty bound by the requirements of the 2007 Safety Health Welfare At Work (General Application Amendments) Regulations Part 3: Electricity to undertake periodic inspections of electrical systems

Frequency of Testing

The Regulations state that every new installation and every major filtration or extension to an existing installation must be inspected and tested by a competent person so as to ensure it is safe.

The Regulations do not state recommended maximum periods between inspection and testing of electrical installations but the age, use and condition of any installations should be taken into consideration when determining the frequency of testing and inspection.

Keeping Records

Records of inspection and maintenance should be kept throughout the life of an electrical system as this will enable the condition of the installation to be monitored.

Condition reports on electrical installations, and records of maintenance and repairs, all help to demonstrate that reasonable steps are being taken to meet their legal obligations.

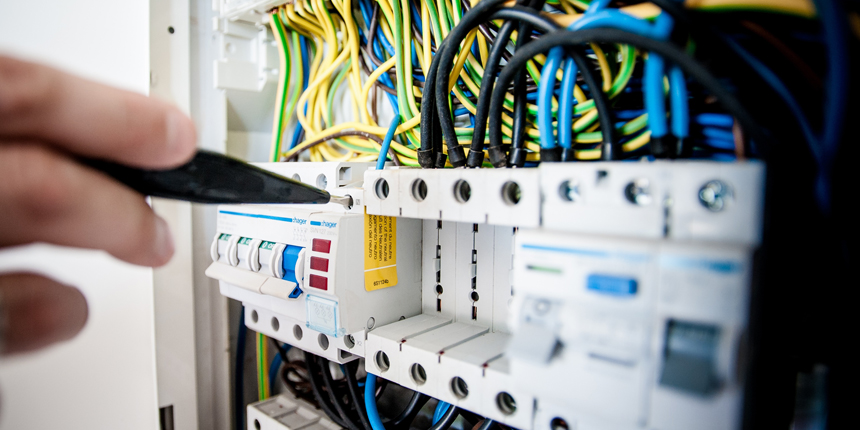

Fixed electrical installation inspections

An independent inspection and test of the installation by a Competent Person such as a fully qualified electrical contractor will help identify hidden problems and deteriorations in a system before they cause serious problems.

Insurers may have specific requirements should an inspection be required as a condition of cover.

Portable electrical appliance inspections (PAT Testing)

Portable electrical appliances (defined as any electrical appliance capable of being carried and connected to a mains supply) should be inspected and tested by a competent person on a regular basis. This doesn’t have to be a qualified electrician, however they should have suitable electrical knowledge and experience, understand the equipment to be tested and be able to recognise if it presents a hazard.

There is no statutory frequency for inspection and testing of portable appliances. Instead the frequency should reflect usage, together with the environment the appliance is generally used in. In other words the greater the frequency and the harsher the environment the shorter the period between testing.

It is good practice to perform a simple visual check before use of equipment to check for damaged plugs, frayed cables and loose connections.

Warning signs

Electrical problems need diagnosis from a professional, and many problems may remain hidden unless inspected and tested. A few common warning signs may include:

- Frequent circuit breaker tripping or fuse blowing

- Flickering lights

- Receiving a mild electric shock or a tingle from appliances or the distribution system

- Evidence of overheating on distribution boards

- Scorch marks or overheated parts; particularly common on high current use appliances like kettles, heaters, toasters, etc.

- Unusual buzzing or hissing sounds, or smells from apparatus or the electrical distribution system

- Malfunctioning light or power switches where the switch throw does not have a clear ‘click’.

More information click here